The Gear We Use and Why It Matters: Inside ECTC’s On-Site Equipment

When people think of traffic control, they usually picture high-vis shirts, cones, and a stop/slow bat. And while that’s not wrong, there’s a lot more to a professional traffic management setup than meets the eye.

At East Coast Traffic Control, we take gear seriously. Not just because it looks the part, but because using the right equipment is essential for keeping people safe — workers, road users, and the community alike.

Here’s a look at some of the equipment we use on the ground every day, and why it matters so much to the way we work.

Cones, bollards and delineators — more than just markers

Our cones and bollards aren’t there for show. They’re the first layer of protection between live traffic and your worksite. We use approved sizes and weights for stability in regional winds, and our crews know how to space and place them correctly to create clear visual guidance for drivers.

On rural roads, visibility is critical. That’s why we also use reflective tape, base weights and separation devices that meet current TMR and Transport for NSW requirements.

Portable Traffic Control Devices (PTCDs)

When the job calls for active traffic control in higher-speed zones or complex setups, we deploy Portable Traffic Control Devices. These are remote-controlled boom gates, portable traffic signals or even automated stop/slow systems that allow for safer control without having a person standing in a live lane.

They’re especially useful on roads with poor visibility or during night works. We use them when the site risk demands a safer alternative to manual stop/slow.

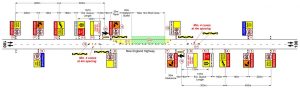

Arrow boards and vehicle-mounted signs

Every applicable ECTC support vehicle is fitted with compliant arrow boards and signage mounts. These aren’t just for show — they alert drivers to lane closures and directional changes well in advance.

We maintain our boards regularly and ensure they meet current MUTCD and RMS guidelines. They’re also bright, reliable, and positioned high on vehicles to maximise visibility in poor weather or low light.

Variable Message Signs (VMS)

When the public needs early warning — detours, changed conditions, upcoming works — we roll out our trailer-mounted VMS units. These programmable boards are placed well ahead of the site and can be updated remotely if the schedule or setup changes.

It’s a key way we reduce driver frustration and help manage speed before vehicles even reach the work zone.

UHF radios and internal comms

Clear communication is everything. That’s why our crews operate with UHF radios, site-specific call signs, and check-in protocols. Whether they’re coordinating a shuttle flow or monitoring plant movements, communication keeps things flowing and prevents incidents.

We also maintain a backup radio or mobile contact for each crew so nothing is left to chance.

Lighting and night work gear

Working after dark means extra caution. Our crews use dedicated night work lighting setups, including floodlights, vehicle-mounted strobes and reflective signage rated for low-light visibility.

We make sure lighting is well-placed — not blinding drivers, but illuminating hazards clearly. Proper lighting reduces the risk of accidents and helps our crews work confidently, even on remote or dimly lit roads.

Frangible signposts and compliance-rated gear

Safety isn’t just about what you see, it’s about how the gear behaves under stress. We use frangible signposts and approved footings so that, if struck, equipment doesn’t become a deadly projectile. Every bracket, base and barrier is chosen for its compliance rating, durability, and safety performance.

This isn’t just good practice. It’s required under modern traffic management standards — and something we take seriously.

Clean, professional setups send a message

The way a site looks says a lot about who’s running it. Our crews are trained to keep signage clean, equipment positioned precisely, and the site tidy. Drivers trust what they see — and a neat, well-managed work zone creates confidence.

It also reflects well on the contractor, council, or event we’re supporting. Whether it’s a road upgrade or a public festival, our gear and our setup are part of the public face of the project.

Regular maintenance, storage and tracking

We don’t just use good gear — we look after it. Our depots manage regular maintenance schedules for signage, trailers, batteries, radios and more. This ensures everything is site-ready before it goes out the gate.

We also track deployment so we know where our gear is, what condition it’s in, and when it’s due for inspection or servicing.

It’s not just about having gear. It’s about using it right.

Having the right equipment is one thing. Knowing how to use it properly is another. Our team is trained to understand why spacing matters, when to switch from cones to barriers, and how to adapt gear placement based on road geometry and traffic volume.

Good traffic management is a balance between the right gear, the right training, and the right attitude. That’s what sets our teams apart.

FAQs

Do you supply your own equipment or use contractor gear?

We supply and maintain all our own traffic control equipment so we can guarantee compliance and quality.

Is your equipment compliant with NSW and QLD standards?

Yes. We use gear that meets current requirements under MUTCD, QGTTM, and TfNSW guidelines.

What’s the benefit of using portable traffic signals?

They reduce the need for people to stand in high-risk areas, especially in night works or high-speed zones.

How do you handle signage for detours or long sites?

We plan site setups carefully, using arrow boards, VMS trailers and advanced placement to give drivers plenty of notice.

Do you service your own equipment?

Yes. Each depot manages regular checks and servicing of our equipment to make sure it’s site-ready at all times.